PRESS RELEASE

Issued by: Irkutsk Aviation Plant

In the course of the visit of the Russia's government First vice president Sergey Ivanov to the Irkutsk Aircraft plant on 25th October 2007 the «Irkut» Corporation President Oleg Demchenko announced the commencement of serial deliveries of the components for Airbus A320 airliners. The nose Landing Gear bays became the first items manufactured by the «Irkut» main production facility – the Irkutsk Aircraft plant. After undergoing proper tests one of the items has been already integrated onto the series A320 airliner at the Airbus plant in Meaulte, France.

Oleg Demchenko pointed out: «Establishing partnership and cooperation with Airbus and EADS is surely having a positive effect upon «Irkut»'s evolution. We are introducing state-of-the-art manufacturing technologies certified against the Airbus standards, thus diversifying production facilities and gaining a stable source of revenue for the long term».

Reference details:

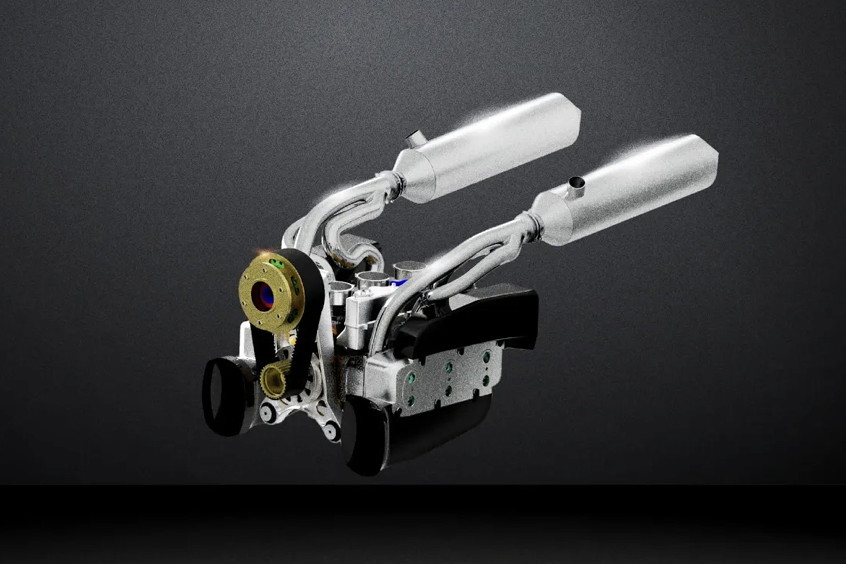

Initial contracts for manufacturing of the keel beams, flap tracks, floor grids and nose LG bays for the A320 family aircraft at the Irkutsk Aircraft plant were concluded in December 2004. These contracts envisage the fulfillment of orders amounting at nearly USD 200 mln within ten years. According to the current estimates the order book is to reach USD 1.985 bln by 2015.

From December 2007 the Airbus components are to be assembled of the Russian-made parts. Next year the plan is to reach the maximum production level under the signed contracts in order to ship the equipment for not less than USD 100 mln yearly starting 2010. The long-term prospects are to achieve an annual turnover of about USD 300 mln.

The signing of the first large-scale contract with Airbus became possible in many respects due to the fact that the Irkutsk Aircraft plant had always paid great attention to the final products' quality. In 1997 it became the first among the Russian military enterprises to receive the certificate of conformity to international ISO 9002 standards. In August 2003 the validity of the certificate was prolonged for another three years. Since January 2006 the Irkutsk Aircraft plant is certificated under ISO 9001standards.

In order to fulfill the contractual obligations the Irkutsk Aircraft plant underwent large-scale preparations for the required Airbus certification procedure, which included the harmonization of Russian and European standards, production facilities upgrade, new machines' procurement and assembly, development and manufacture of tooling, sample testing, trying out logistics' philosophy and procedures.

The preparatory activities coincided with the fundamental technical re-equipment of the Irkutsk Aircraft plant manufacturing facilities, which required USD 120 mln of investments allocated by the «Irkut» Board of Directors.

Within the scale of technical re-equipment the following top-notch equipment was procured, assembled and mastered: around 30 efficient machines and machining centers; over 40 test chambers and labware; more than 10 galvanic and coating lines.

The new galvanic workshop that has no analogues in Russia worth USD 15 mln was set up. The luminescent control shop has been constructed. The new technologies for machining processing and aggregate assembly were acquired.

To introduce the up-to-date standards system «Irkut» has received 1924 standards from Airbase and procured 696 international and modern national standards.

Special training programs were developed and introduced at the Irkutsk Aircraft plant. «Irkut» staff has undergone special training at partner-plants in Germany and France.

Thanks to the above measures the «Irkut» Corporation became the firs Russian aircraft manufacturing enterprise certified as an Airbus supplier. Production facilities at the Irkutsk Aviation Plant are completely certificated under Airbus standards.

In the course of implementing the international industrial cooperation project the Irkutsk Aircraft plant gains the unique experience of mastering cutting-edge technologies, certified against Western standards, required for production of the civil airliner airframe and its final assembly. This competence has already proved useful while creating Russian passenger aircraft MC-21. For the board of United Aircraft Corporation (UAC) has identified the «Irkut» Corporation as the head contractor in MC-21 program. Successful implementation of this program shall ensure Russia's resurgence at the world market as an independent competitive passenger-aircraft manufacturer.

| Contact details from our directory: | |

| Irkutsk Aviation Plant | Airframer |

| Airbus S.A.S. | Airframer |

| Related aircraft programs: |

| Airbus A320 |

| Related directory sectors: |

| Landing Assemblies |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390