PRESS RELEASE

Issued by: MicroStrain Inc.

Frost & Sullivan has acknowledged MicroStrain® , for the second time, by awarding the Company the 2007 Frost & Sullivan North American Technology Innovation Award in the field of energy harvesting.

MicroStrain's® ESG-LINK™ Energy Harvesting Wireless Strain nodes will operate indefinitely without the need for batteries, by converting cyclic strains into DC using piezoelectric material. ESG-LINK™ features an energy harvesting power conversion and storage electronics unit, signal conditioner, low-power system microprocessor, precision time-keeper, non-volatile memory for on-board data logging, and a frequency agile IEEE 802.15.4 transceiver. Sample rate and duration, sensor offset and gain, and on-board shunt calibration are all wirelessly programmable. Reducing power consumption is a key requirement when energy harvesting, because the energy "checkbook" must be balanced to support continuous operation.

ESG-LINK™ adapts its operating mode depending upon the amount of available energy. ESG-LINK™ logs data to memory and checks to see if enough energy has been stored to transmit data over the RF link. If enough energy is available, data are transmitted, if not, data are logged to memory and transmitted when sufficient energy is available.

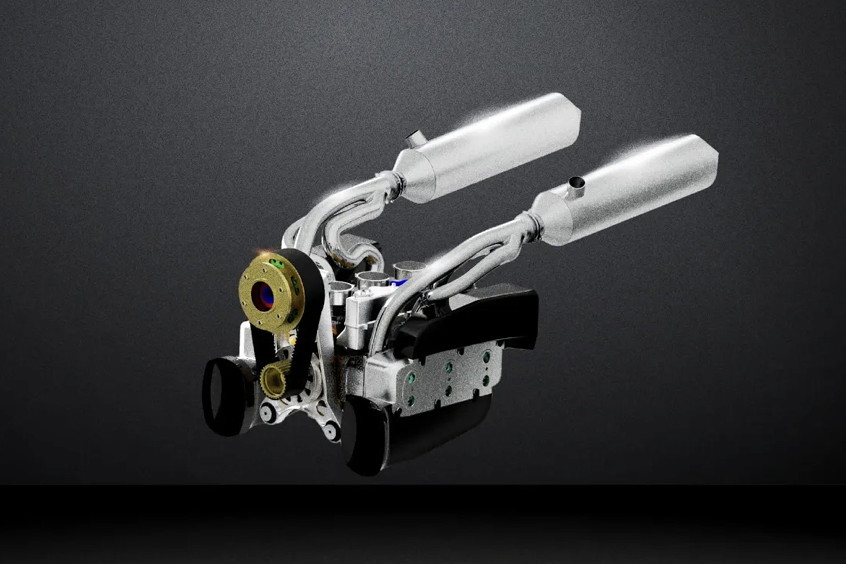

ESG-LINK™ nodes were recently flown on a Bell Helicopter, operating continuously without batteries. Continuously monitoring the strains on rotating components, the nodes can record operational loads, compute metal fatigue, and estimate remaining component life. ESG-LINK's™ were used to measure the strains applied to pitch links, which control the pitch of the rotor blades. Pitch link loads vary depending upon flight regimes and are therefore an excellent indicator of vehicle usage severity, and can provide critical data for improved condition based maintenance.

While spinning at 300 rpm, data were logged within the ESG-LINK's™ non-volatile memory and periodically transmitted to a small mobile base station located in the helicopter's cabin. Flight test data from ESG-LINK™ nodes were compared to data collected by hard-wired strain gauges (using slip rings) with close agreement.

As strain energy profiles for each application are different, MicroStrain will work with customers to optimize the energy harvesting ESG-LINK™ for their applications. MicroStrain has made significant advances in strain-based energy harvesting technology for aircraft applications and are ready to collaborate with aircraft manufacturers in commercializing the technology. Applications in condition-based monitoring of machinery components and structural health monitoring are also projected in MicroStrain's future. Reliability, robustness, low power consumption high efficiency, and the capability to replace batteries are the distinctive features of MicroStrain's® technology, which make it unique. Hence, Frost & Sullivan is pleased to honor MicroStrain with the 2007 Technology Innovation Award for its significant developments in the field of energy harvesting technology.

"If major strides in mechanics and mainframe computers dominated the march of technology in the 20th Century, it is the realm of microelectronics that will dominate the next 100 years," said Senator Patrick Leahy. "Vermont companies like Microstain Inc. of Williston are at the leading edge of this research, applying the latest advances to deal with real problems. Microstrain's® unique energy harvesting sensor will allow sustained monitoring of strain on structures as large as a bridge or devices as small as an artificial knee replacement. The Frost & Sullivan Award for Technology Innovation testifies to the quality and significance of Microstrain's® work."

| Contact details from our directory: | |

| MicroStrain Inc. | Test Equipment, Attitude and Heading Reference Systems |

| Related directory sectors: |

| Test Equipment |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390