PRESS RELEASE

Issued by: Irkut Regional Aircraft (was Sukhoi Civil Aircraft)

The Sukhoi Superjet 100 aircraft scored 25 hours 55 minutes in-flight during the first stage of factory-based flight tests, with an average flight lasting 2-4 hours.

At this stage the test program goal is to conduct initial in-flight evaluation of aircraft aerodynamics and general performance. Aircraft systems and equipment functioning is checked at various configurations of wing control surfaces with both retracted and extracted landing gear positions. The testing was performed at the altitude up to 3000m with 35000-40000kg take-off weight at 670-680km/h maximum speed.

"We've covered quite a large volume of initial in-flight evaluation program having checked the performance of engines, APU, fly-by-wire as well as the other key aircraft systems. It's encouraging that stability and control at all landing gear and flap configurations, take off and landing performance fall into the expected results, proving the earlier aerodynamic, system and simulation data, earlier obtained through the large series of bench-testing", - said Alexander Yablontsev, the Chief Test-Pilot of Sukhoi Civil Aircraft Company.

"Rapidly soaring fuel prices make an aircraft fuel efficiency a core to its global competitiveness, - remarked Victor Soubbotin, President of Sukhoi Civil Aircraft Company, commenting on the results of the first series of flights, - The first stage of factory-based flight test brought us the first in-flight hourly fuel consumption data. Its projection over the cruise mode lets us judge that the aircraft is going to consume less than 1,7 tons per hour, which justifies competitive advantages in terms of fuel efficiency declared earlier".

Concurrently with flights, production sites in Komsomolsk are manufacturing both further prototypes and the aircraft intended for the delivery. All aircraft systems had already been installed on SSJ100#95003 and it's been powered on, which allows for factory system trials. SSJ100#95004 had its fuselage joint with the outer wing and is currently fitted with the systems. Assembled fuselage of the fourth flight aircraft (SSJ 100#95005) has been recently shipped to the final assembly shop, while outer wing production is in completion. In the meantime, KnAAPO is putting together centre, cabin and rear sections of the fatigue aircraft (SSJ100#95006).

All manufacturing sites – KnAAPO, NAPO, and VASO – continue parts production for the first four aircraft to be delivered to the airlines. A centre section assembly of the first delivery aircraft, the seventh in succession of the SSJ100 family, began in Komsomolsk in June.

| Contact details from our directory: | |

| Irkut Regional Aircraft (was Sukhoi Civil Aircraft) | Airframer |

| Related aircraft programs: |

| Sukhoi SuperJet 100 (SSJ) |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

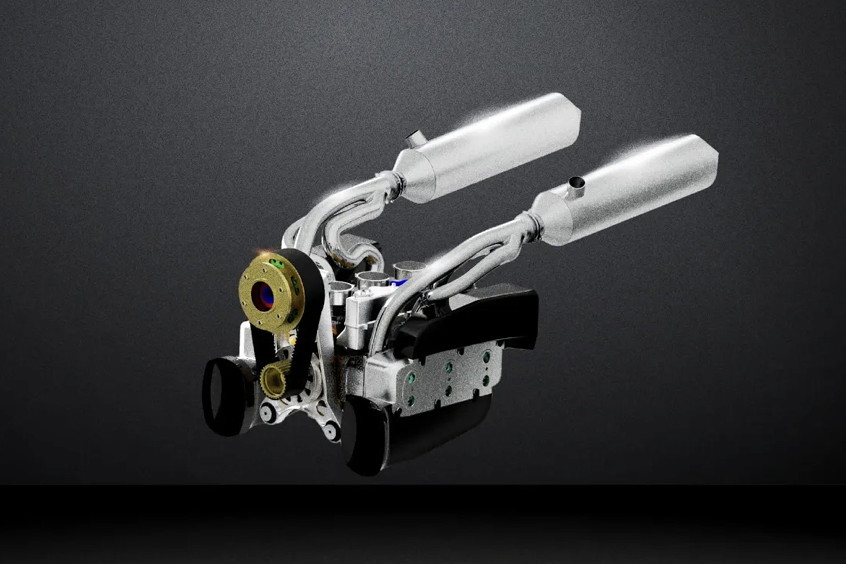

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390