Shorter grinding times and high material removal are requirements every user of vibratory finishing machines requires. As a result of the close co-operation with a leading aviation company, Rösler engineers designed and constructed a rotary vibrator system unique in its performance. The new "high-speed" machine series reduces processing times by almost half compared with the processing times achieved with conventional rotary vibrator technology.

The customer is among the most important partners of the globally active turbine blade manufacturer and numerous vibratory finishing machines to grind, smooth and polish a variety of different turbine blades operate there daily. Typical to such safety parts which are subject to high stresses is the use of high-quality materials such as nickel-alloyed special steels and titanium.

Processing surfaces of forged parts involves a high level of machining work and therefore long grinding times. In order to keep these as short as possible, high energy disc finishing machines, which allow up to 30 times more intense processing than conventional vibratory finishing machines, are deployed. However, the use of this very powerful machine technology is limited by the size of the components and the cost-benefit ratio as there are many different kinds of turbine blades to be processed. It was therefore suggested by Rösler to additionally deploy vibrators of the Euro model series to process this type of component. As certain work steps require processing times of up to fifteen hours, both - the user as well as Rösler – developed the idea of reducing the process grinding times for such special applications.

From an Idea to Reality

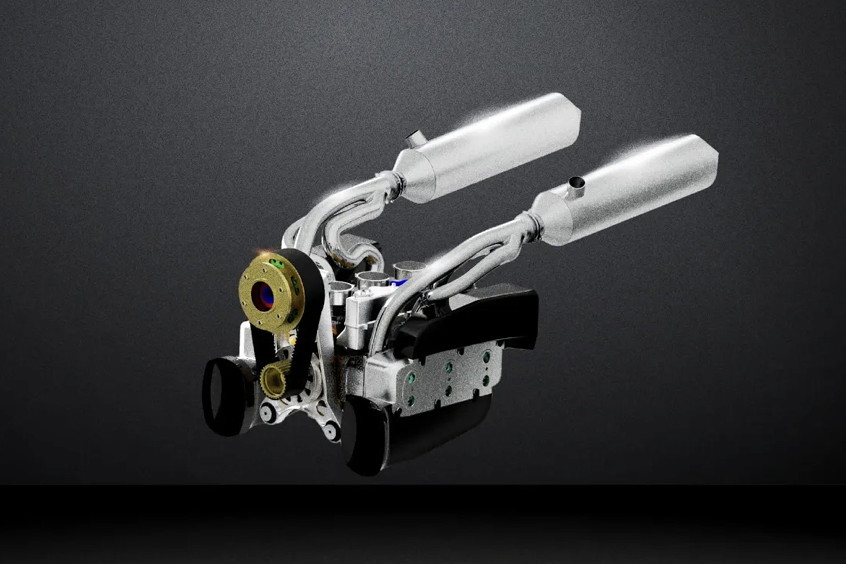

There were many ways to approach the task of achieving a more powerful performance on the basis of the Euro rotary vibrator series. The central part here: a heavy-duty drive unit with a driving power of 12.5 KW (17 HP). However, the processing bowl, machine substructure, processing bowl spring bearing as well as other details had to be redesigned and adapted.

Trial Runs

New developments at Rösler are applied at first in the test centre where they are tested thoroughly for performance, properties and functions. The input results quickly reveal what could be expected of this new development: compared with conventional vibrators, running times here could be reduced by almost half whereby the material abrasion remained the same! This outcome far exceeded the developers' and the customer's expectations.

Proven in Practice

Apart from the test machine a few more units are now operating at the customer. The machine's performance is indeed fascinating: shorter grinding times, the same material abrasion and, at the same time, just forty per cent higher consumption of abrasive media. The system therefore makes sense also from an economic point of view. The outstanding feature of the high-speed rotary vibratory series is the up to sixty per cent improved grinding performance. In particular, the machines are suitable to process robust components such as forged, cast and punched parts.

| Contact details from our directory: | |

| Rösler UK Limited | Blast Finishing Equipment, Additive Manufacturing, Blast Finishing Media, Blast Finishing Services, Paint Stripping, Metal Finishing/Polishing, Shot Peening, Abrasive Equipment, Barrell Finishing Services |

| Related directory sectors: |

| Surface Treatment |

| Production Equipment |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390