PRESS RELEASE

Issued by: Airbus S.A.S.

Airbus is adopting a low cost, real-time visualisation system for locating items in its plants. The project, launched in October 2014, uses smart, connected boxes and carts to track equipment across the whole supply chain, from supplier premises right up to the assembly point. A full-scale trial of the system was conducted at Airbus sites in both Saint-Nazaire and Saint-Eloi in early 2015. Its results demonstrated the technology's potential and the project team will industrialise its system for use across all Airbus sites.

Benefits demonstrated include better optimised stock rotation and significantly reduced time spent looking for logistics means on the shop-floor. The system is based around GPS system combine to long-range outdoor tracking using 'Ultra Narrow Band' (UNB) technology. For the project, Toulouse start-up company Sigfox was enlisted to develop the specially designed global network for linking the 'connected' devices. Smart boxes transmit the objects' GPS coordinates to Sigfox's antenna, which sends the information on to Airbus via the internet. The result is that every piece of equipment can be pinpointed exactly in real-time. The application can also generate alerts if, for instance, it goes outside its desired route or spends too long at an Airbus site or a supplier's premises.

The project team also created a special application to view this information on a PC, tablet or smartphone, thanks to technical and financial support from Airbus' “Bizlab” initiative – which helps new innovative projects become operational re

| Contact details from our directory: | |

| Airbus S.A.S. | Airframer |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

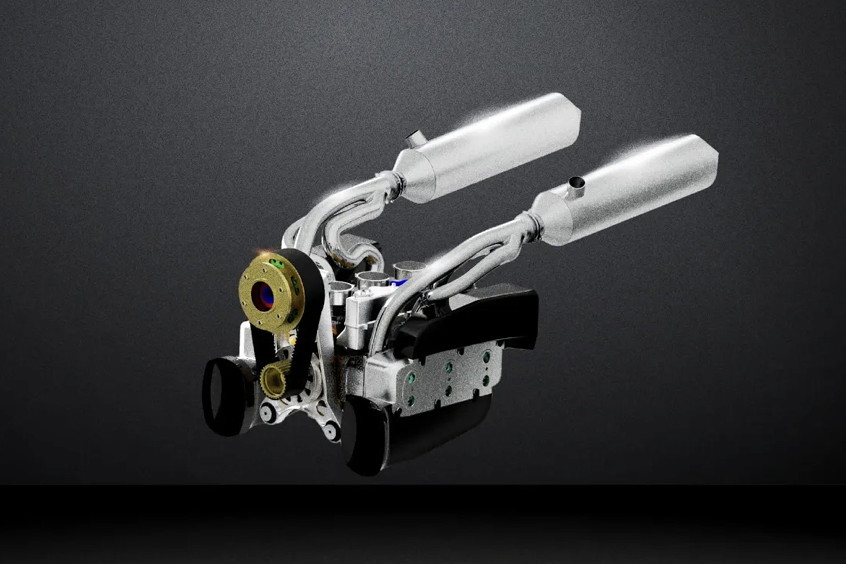

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390