PRESS RELEASE

Issued by: Green Charter 2022

A leading composites components manufacturer has urged leading aerospace firms to look again at the supply industry's production expertise, announcing that the sector is "open for business".

Graham Mulholland, managing director of epm: technology, made his plea in a speech to the Thermoplastics Composites Technology and Business event, which was hosted by the National Composites Network and Advantage West Midlands at RAF Cosford on April 21.

Delegates, who included representatives from Airbus, GKN and Lockheed-Martin, heard Mr Mulholland admit how the composites supply industry had lost credibility in the past by failing to provide solutions to how hi-tech materials can be produced on a scale that would suit the aerospace industry.

But he said that companies have now learned the necessary techniques and developed the know-how to put the process technology into practice, enabling them to work effectively with the supply industry's own composites developers on the next generation of aircraft.

Mr Mulholland said: "The composites industry has in the past shot itself in the foot by being too fixated on developing the materials and not developing manufactures or appropriate processes to make the components.

"This undermined confidence in the industry and aerospace companies decided they would develop the production side of composites components themselves.

"Millions of pounds is being invested in composite components for aerospace, most notably at GKN Aerospace – Filton, and the material is undoubtedly at the centre of 21st Century aerospace technology.

"However, I believe that there is now a knowledge gap within the aerospace industry when it comes to the practicalities of supplying composite components on the correct scale to meet fluctuating demands.

"Our industry has developed that expertise and if aerospace manufacturers came to the component supply industry again, they will find we are open for business."

Mr Mulholland's speech marked epm: technology's entry to AdComp (West Midlands), a new body backed by the NCN and Advantage West Midlands which will create a cluster of excellence in the West Midlands to develop and sell world-class thermoplastic composite parts.

Adcomp partners will develop new processes for the affordable and rapid forming of high performance thermoplastic composites and work together to develop the composites supply chain within the region.

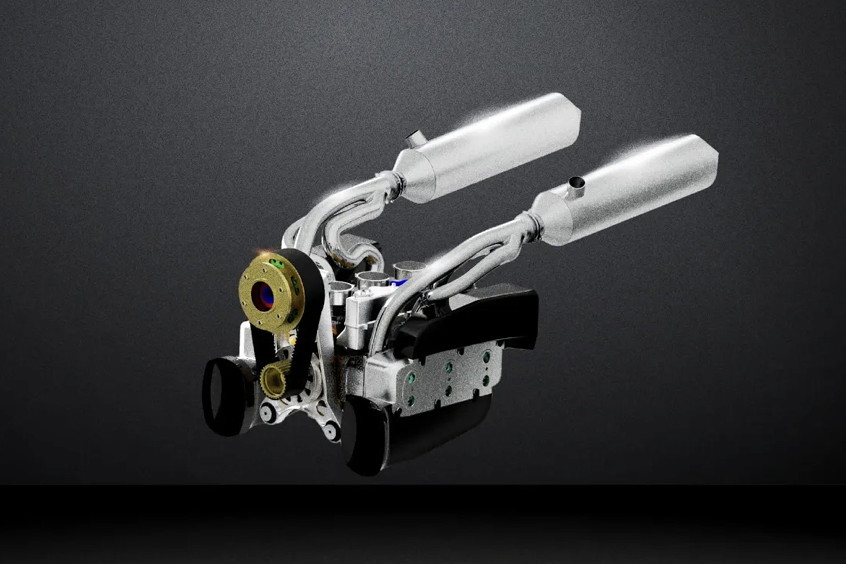

epm, which is based in Derbyshire, has worked with Bombardier and Rolls-Royce on developing aerospace components previously but has made its name as a foremost producer of composite components to elite motorsport teams.

It produces components for five Formula One teams - which is unprecedented in the composites industry - as well as to World Rally and touring car teams, arenas where the demands are such that epm had to develop its production techniques to meet tight deadlines and exacting specifications.

Mr Mulholland added: "The demands of our current customers have forced epm to find new production techniques and processes.

"That development is ongoing and has enabled us to push back the boundaries of composite manufacture. We have had to prove our systems have the scale and they can support all the necessary inputs. The main goals are to have consistency in all our numbers so when we quote a project or component price it is trusted.

"We are more than willing to share those experiences and discuss our innovations with the aerospace industry. The Airbus A380 and forthcoming A350 project offer big challenges for UK manufacturing and I am confident that composite companies outside the aerospace industry could have a bigger role to play."

| Contact details from our directory: |

| Related directory sectors: |

| Composites |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390