PRESS RELEASE

Issued by: LAI International, Inc.

LAI International, Inc., strategic supplier of precision components and subassemblies for original equipment manufacturers, announced it has expanded its Advanced Hole-Drilling Production Center to process turbine components for power generation and aerospace industries.

The expansion, which took place at LAI's contract manufacturing plant in Minneapolis, increases production capacity by 25 percent for high-speed waterjet coating removal, drilling and machining of shaped holes. The Advanced Hole-Drilling Production Center also features a development laboratory and flow-testing workstations that support drill-to-flow methods to achieve optimum flow performance and precise control in turbine components.

"The latest waterjet workstations and supporting equipment are specially designed by our engineering group for advanced shaped hole drilling in a production environment and will increase our capacity to service our customer's demands even more efficiently than before," Frank Bailey, plant manager of LAI's Minnesota facility, said.

LAI's engineering staff has pioneered development of processing shaped cooling holes using an enhanced abrasive waterjet technology that eliminates thermal distortion, re-cast layers and the need for secondary operations. LAI's Advanced Drill-to-Flow Abrasive Waterjet ProcessTM drills precision shaped holes to diameters as small as 0.018 inches.

"Our innovative process provides a number of advantages over non-traditional machining methods, such as reducing cycle-times, producing superior hole quality and allowing greater design freedom," Darcy Dodge, director of strategic products for LAI.

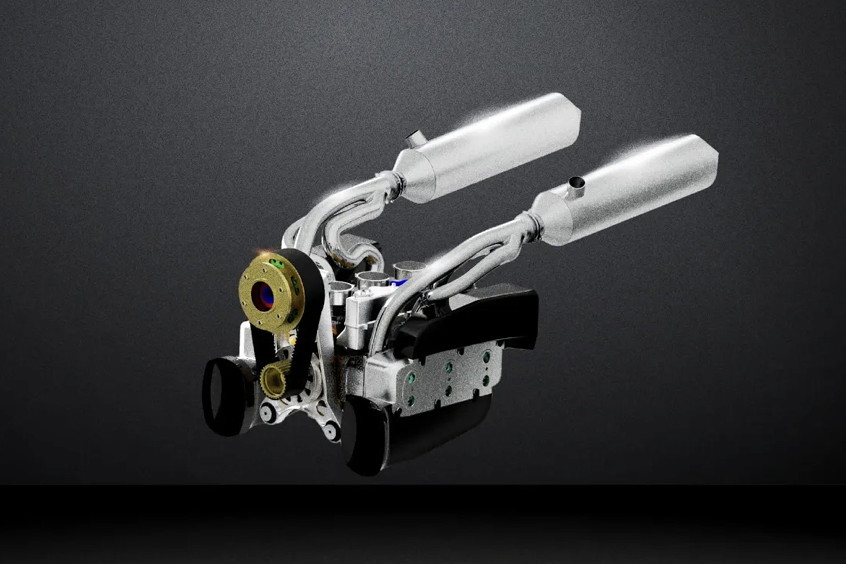

The process also allows for tighter flow control, improved hole profiles, elimination of re-cast layers and lower processing costs. The company's specialized waterjet operations, which are used to cut slots in spacer bands and rings, excel at near-net cutting of difficult-to-machine materials, including stainless steel, Inconel, titanium and high-nickel-content super-alloys. The world leader in precision shaped hole drilling with abrasive waterjet technology, LAI processes blades, buckets, blisks, shrouds, nozzles, vanes, impingement plates and other precision turbine parts.

The company uses advanced laser, EDM, abrasive waterjet, CNC grinding and CNC milling technologies to process precision components for industrial and aerospace gas turbines. LAI's precision five-axis laser machining centers cut, weld and drill pre-formed, three-dimensional and rotary parts.

| Contact details from our directory: | |

| LAI International, Inc. | Heat Treatment, Laser Cutting, Waterjet Services, Machining Services, Laser Drilling, Aircraft Structural Components |

| Related directory sectors: |

| Processes |

| Machining |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390