The BIKAR Group is investing heavily in the future and further expanding its production capacities, particularly for the supply of the aviation industry. With the official groundbreaking for the BIKAR Zone East at the Korbußen site in Thuringia, the company is expanding its production facilities with another state-of-the-art cutting centre for non-ferrous semi-finished metal products, thereby achieving a new dimension in aerospace manufacturing. BIKAR Aerospace GmbH is setting up the new production plant, which is to be the largest fully automated centre of its kind in the world, at a cost of €60 million.

Investment in technology and people

‘This investment is a strategic milestone in our efforts to drastically expand our capacities for the aviation industry. We already supply high-precision blanks to well- known aviation companies worldwide. With BIKAR Zone East, we are setting new standards in terms of quality, efficiency and automation,’ explains Alexander Bikar, CEO of BIKAR Aerospace.

Global expansion and major success with Sonaca

BIKAR has established itself as one of the leading suppliers to the aerospace industry and is continuously expanding its global presence. In addition to its headquarters in Bad Berleburg, the company has subsidiaries in Bristol, UK, and Belagavi, India, to serve international customers even more efficiently. A significant success in this growth process is the multi-million euro deal with Sonaca, one of the world's leading manufacturers of aerostructures.

Mark Roberts, Global Sales Director of BIKAR Aerospace, emphasises: ‘With this order, we are demonstrating that we operate at the highest level as a strategic partner to the aviation industry. Our customers expect precise, timely and efficient deliveries – and that is precisely what we are optimising our processes for with BIKAR Zone East.’

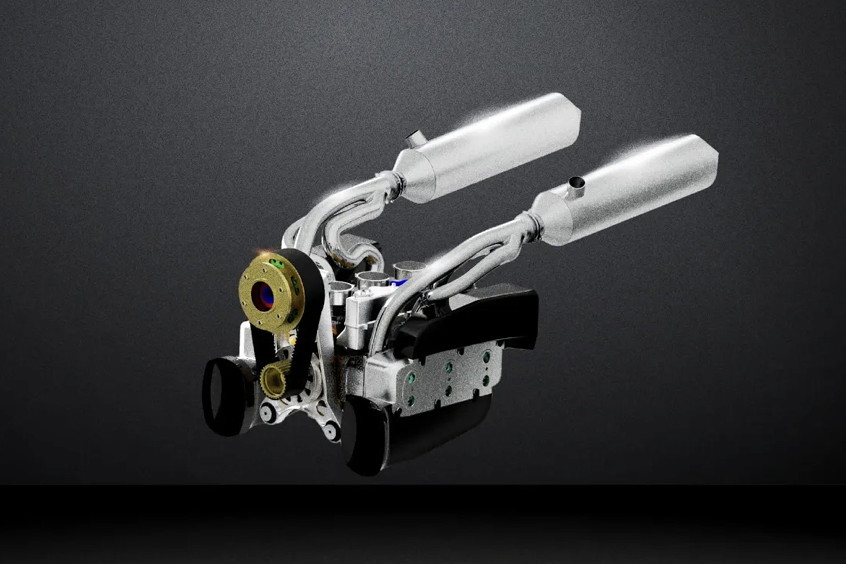

Technological excellence for the aerospace industry

The new plant relies on highly automated processes: intelligent high-bay storage, robotics, autonomous floor vehicles and high-tech saws ensure fully digitised production. These innovations significantly increase quality and speed in the cutting business. BIKAR's energy-efficient design and optimised production processes also underscore the company's commitment to sustainability in the industry. The importance of this major project for the aviation industry has also been recognised by the world of politics. Michael Kellner, the German government's representative for SME businesses, explained: ‘The BIKAR Zone East is an impressive example of how German companies combine innovation and sustainability. This investment not only strengthens the domestic economy, but also makes Germany more competitive internationally as a high-tech location. The strategic investment of the BIKAR Group underpins its position as a global innovation leader and reliable partner to the aviation industry. With BIKAR Zone East, the company is taking its metal cutting capabilities to a new level and actively shaping the future of the industry.

| Contact details from our directory: | |

| BIKAR Aerospace GmbH | Aluminium, Metal & Alloy Suppliers |

| Sonaca SA | Metal Bonding, Laboratory Testing Services, Aircraft Structural Components, Metal Structures, Composite Structures, Fabricating Services, Machining Services, Precision Machined Parts, Composite Manufacturing Services, Injection Moulding, Aircraft Doors, Ice Protection/Prevention Equipment, Nose Cones, Fuselage Sections, Wings, Flap/Slat Mechanisms, Certification Services |

| Related directory sectors: |

| Metals |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390