PRESS RELEASE

Issued by: BIKAR Aerospace GmbH

The metal specialist BIKAR Aerospace, as part of a long-term partnership, is to become the new main supplier to Sonaca Belgium, a leading company in the manufacture of aerospace parts. A long-term agreement has now been signed for the supply of aerospace aluminium plates and sheets to Sonaca with value added services. The agreed contract volume is the largest in BIKAR’s 62 years of company history. To process the agreed delivery quantities, BIKAR Aerospace has expanded its production capacities at its sites in Germany and is focusing on digitalisation and lean production.

With the start of the contract in early 2025, the aviation experts at BIKAR Aerospace will provide comprehensive procurement, warehousing, processing and commissioning services for materials required just-in-time at the Sonaca facility in Gosselies, Belgium.

BIKAR Aerospace was selected as a partner following comprehensive qualification and control audits, during which the company successfully demonstrated its expertise in fulfilling Sonaca's strict supplier requirements. When selecting its partners, Sonaca says it focusses on the continuity of top quality and delivery reliability, reducing overall process costs and promoting innovation. The forward-thinking approaches and new technologies implemented at BIKAR Aerospace were decisive factors in favour of the German company. This co-operation represents the largest contract value ever awarded by Sonaca Belgium to a single supplier active in this commodity.

“We are proud to have secured this contract. Our digital and automated solutions have aided us in finalising this significant agreement, highlighting our pioneering spirit in the aerospace market. Our outstanding internal, cross-functional collaboration has made a crucial contribution to the successful conclusion of the contract," says Janek Müller, Head of Aerospace at BIKAR's headquarters in North Rhine-Westphalia, Germany.

End-to-End Solutions thanks to investments and digitalisation

To create additional production capacities tailored to the requirements and needs of the customer, BIKAR Aerospace is establishing the second fully automated cutting center for non-ferrous metals, the BIKAR Zone East, at its site in Korbussen, the region of Thuringia. In this state-of-the-art machining center for plates and sheets, automation concepts successfully tested in the serial production of other industries are adapted, enabling extremely flexible and comprehensive processing of aluminium semi-finished products even for individual pieces and small series.

This includes the automated storage of raw plates in the high-bay warehouse, its direct connection to several robot-guided sawing lines, driverless transport systems, fully automated scrap handling including extraction and pressing of the shavings as well as robot packaging of the finished blanks. The interconnection of individual plant components is achieved through a specially developed control logic. Intelligent algorithms and seamless integration with the internally developed and hosted ERP system NEXT enable the automated control of the entire manufacturing facility. This paves the way for dynamic, real-time optimised and self-organising value creation processes at BIKAR.

For Sonaca, this represents an efficient and reliable end-to-end solution for sensitive material components in aerospace parts. Non-standardised dimensions, preparatory milling work and logistically efficient packaging of non-ferrous metals are just some of the requirements that BIKAR Aerospace fulfils for its customers thanks to the implementation of digital and automated manufacturing processes.

"We are confident that with the BIKAR Zone East, we are taking a significant step closer to our goal of becoming the leading supplier of aluminium in the aerospace industry," says Dr Jan Wolf, Chief Information Officer (CIO) at BIKAR. He adds: "Our aim is to implement process automation, digitalisation and optimisation in all areas using the latest technologies, in particular to simplify and speed up processes, perfectly tailored to the needs of our customers and our company."

BIKAR Aerospace masters the demands of the aviation business

Customised software solutions optimise the ordering process, enabling BIKAR Aerospace to respond as quickly as possible to its customers' material call-offs and planning. This ensures an efficient production process for Sonaca and guarantees that deliveries always meet the agreed-upon schedules and quality standards. A Contract Monitoring Tool provides Sonaca with real-time inventory data, enabling constant alignment of the required goods in Belgium with the inventory at BIKAR. This forecast monitor ensures Sonaca has a secure overview of the supply chain at all times, allowing for early responses to uncertainties in the global market.

Since 2016, BIKAR Aerospace has successfully established itself as a metal

service centre for the aerospace industry. The Sonaca deal further solidifies BIKAR's position as a global player. With the commissioning of the new plants in Bristol, England and Belagavi, India, as well as further planned branches worldwide, BIKAR Aerospace strategically expands its international presence to meet the needs of the aerospace industry. The focus is clearly on offering all services related to material procurement, preparation and delivery from a single source. With the development of its own software solutions and the intelligent networking of systems, the long-established company is successfully forging a path into the digital future of the metal trade.

| Contact details from our directory: | |

| BIKAR Aerospace GmbH | Aluminium, Metal & Alloy Suppliers |

| Sonaca SA | Metal Bonding, Laboratory Testing Services, Aircraft Structural Components, Metal Structures, Composite Structures, Fabricating Services, Machining Services, Precision Machined Parts, Composite Manufacturing Services, Injection Moulding, Aircraft Doors, Ice Protection/Prevention Equipment, Nose Cones, Fuselage Sections, Wings, Flap/Slat Mechanisms, Certification Services |

| Related directory sectors: |

| Metals |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

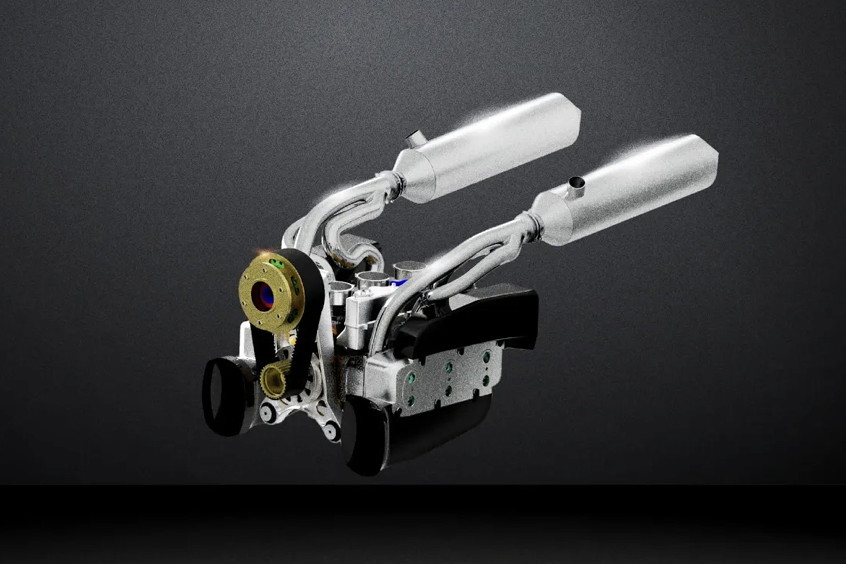

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390