Henkel Adhesive Technologies has collaborated with Boeing to develop Loctite EA 9365FST, a new two-part epoxy adhesive that reinforces and bonds thermoplastic and thermoset substrates and can serve as a matrix resin on fibreglass to strengthen the thin walls of thermoplastic assemblies. Developed for use in aircraft interiors, the halogen and antimony-free adhesive meets industry fire retardancy, smoke density and toxicity (FST) requirements, is REACH and EH&S compliant worldwide, and is qualified to Boeing process specification BAC 5568.

Loctite EA 9365FST cures in just two hours at 70°C (158°F) or in seven days at room temperature. The adhesive is said to offer good mechanical performance when bonding properly treated thermoplastics and thermosets to a range of other substrates. The epoxy provides a balance of adhesion performance and FST compliance. Designed not to yellow over time, the product is paintable, delivering good color performance with less show-through than older adhesive formulations.

When used as a matrix resin, Loctite EA 9365FST easily wets out fibreglass, strengthening thin thermoplastic assembly walls for enhanced structural support in interior applications including wall, ceiling and floor panels; compartments and cabin stowage; galleys; lavatories and seating. The product is available globally and has targeted applications in commercial aviation, defense and rail applications.

"Loctite EA 9365FST is a high-tech, FR and FST-qualified technology that has expanded Henkel's already robust paste adhesive portfolio," explains William Smoot, Technical Account Manager at Henkel Adhesive Technologies. "This product answered a need at Boeing and across the aerospace and rail industries for critical flame retardancy, toxicity and smoke suppression adhesives for cabin interiors. Product safety and sustainability are increasingly important. This product is sustainable and REACH-compliant with no halogens or other hazardous chemistries."

| Contact details from our directory: | |

| Henkel AG | Abrasive Materials, Adhesives, Chemicals, Coatings, Conversion Coatings, Corrosion Inhibitors, Cutting & Machining Oil, Epoxy Resins, Laminates, Metal Stripping, Mould Release Agents, Moulding Compounds, Paint Solvents, Paint Stripping, Potting Compounds, Prepreg, Resins, Surface Cleaning, Thermoplastics, Thread Anti-Seize Compounds, Thread Locking Compounds, Water Treatment Chemicals |

| Related directory sectors: |

| Adhesives |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

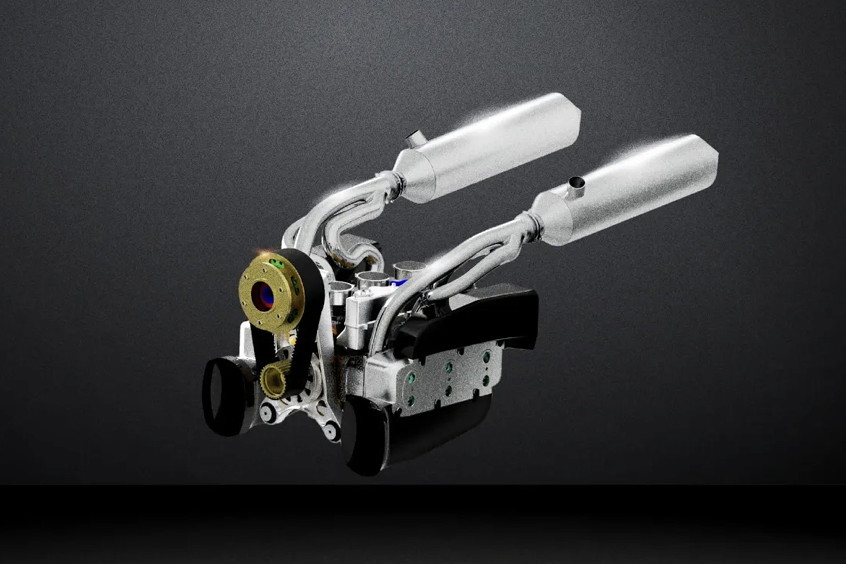

EDGE launches Powertech for high-performance aero engines

GE uses exascale supercomputers for Open Fan engine

Embraer begins assembly of Austria’s first C-390