When Crane Aerospace & Electronics, a major supplier of systems and components for critical aerospace applications, was developing a new tyre pressure monitoring system for the landing gear of Boeing 777 aircraft, it specified VICTREX® PEEK™ polymer for the hubcaps containing the system because of the material's high temperature resistance and high mechanical strength as well as its chemical resistance to the caustic elements found on the runway.

According to Jeff Tonn, Design Engineer at Crane, "The tyre monitoring system on the Boeing 777 is designed to assure proper tyre air pressure for take-off and landing. The hubcaps include a conduit which allows a rim mounted pressure sensor to communicate with an onboard system providing real time data to the cockpit. Maintaining proper tyre pressure is critical to aircraft safety." In addition to Boeing 777 aircraft, the Crane Tyre and Brake Monitoring System may be selected for use on other commercial aircraft.

Aircraft landing gear must be able to survive some of the most extreme environments and loading conditions. "For example," explains Tonn, "Temperatures at altitude can be as low as -54°C (-65°F) whereas temperatures on braking can reach more than 200°C (392°F). Landing gear must be able to withstand repeated hard landings as well as impacts from flying debris. In addition, landing gear is exposed to both ozone and to chemicals in jet fuel, hydraulic fluid and de-icing solutions."

Using VICTREX PEEK polymer enables the hubcaps to withstand these extreme conditions. Explains John Walling, Regional Business Manager for Victrex, "VICTREX PEEK polymer maintains its mechanical properties in hot/wet environments. With a Continuous Use Temperature of 260°C (500°F), the polymer has proven to be the most stable when compared to other high heat thermoplastics. It exhibits no loss in tensile strength after ageing at 200°C (392°F) for one year."

In addition to outstanding thermal performance, VICTREX PEEK polymer has excellent fatigue performance, wear resistance, and chemical resistance. Adds Walling, "This unique combination of properties has allowed VICTREX PEEK polymer to successfully displace metals, traditional composites and other plastics in a growing number of aerospace applications."

Weight also played a major factor in selecting VICTREX PEEK polymer to displace aluminium for the hubcaps. "By specifying VICTREX PEEK polymer, each hubcap now weighs less than 7 kg (1.5 lbs)" says Tonn. "With 14 wheels per plane, the weight reduction is considerable."

Another advantage of VICTREX PEEK polymer is that it can be easily fabricated into tight tolerance parts. "The hubcaps are injection moulded and painted to provide an added layer of UV protection," says Walling. "A nominal wall thickness of 3.75 mm is thick enough to protect the hubcap from high impact events. Moulds are filled evenly on conventional equipment with standard viscosity VICTREX PEEK polymer."

Altek, a custom manufacturer in Liberty Lake, Washington ( HYPERLINK "http://www.altek-inc.com" www.altek-inc.com) with moulding, machining, and aerospace certified painting expertise in VICTREX PEEK polymer for the aerospace industry was given the nod to produce the finished product. According to Mark Adams, Program Manager at Altek, "Through a concerted effort with Victrex and its technical team, we were able to develop a stable and automated moulding process. Victrex was able to offer support during all phases of our operation. Our extensive machining and aerospace painting experience made the secondary finishing go like clockwork. The design and processing guides were very helpful. We were all very pleased at how easy it is to work with this material."

For more information on the properties and performance advantages of VICTREX PEEK polymer, visit the Victrex website at HYPERLINK "http://www.victrex.com" www.victrex.com.

About Victrex

Victrex plc is the leading manufacturer of high performance materials, including VICTREX® PEEK™ polymer, VICOTE® Coatings and APTIV™ film. These materials are used in a variety of markets and offer an exceptional combination of properties to help processors and end users reach new levels of cost savings, quality, and performance.

The company is headquartered in the UK. Invibio®, Victrex's biomaterials business, provides access to specialized products and services for medical device manufacturers. Victrex Japan, Inc. is a wholly-owned subsidiary of Victrex plc. For more information visit http://www.victrex.com or www.victrex.mobi.

VICTREX® is a registered trademark of Victrex Manufacturing Limited. PEEK™, PEEK-HT™, APTIV™ and MAX-Series™ are trademarks of Victrex plc. VICOTE® is a registered trademark of Victrex plc.

| Contact details from our directory: | |

| Victrex Plc | Powder Coatings, Prepreg, Polymer Composites, Thermoplastics, Plastic Tubing, Plastic Films, Plastic Resins |

| Crane Aerospace & Electronics | Battery Chargers/Analysers, Power Distribution Equipment, Hydraulic System Valves, Hydraulic Pumps, Pressure Detectors, Passenger Seating, Centrifugal Pumps, Rectifiers, Fuel Flow Rate Indicators, Position Indicators, Brake System Components, Power Conversion Equipment, Airborne Electrical Power Supplies, Proximity Control Systems, Proximity Sensors, Mechanical Actuators, Tyre Pressure Monitors |

| Related aircraft programs: |

| Boeing 777 |

| Related directory sectors: |

| Landing Assemblies |

| Composites |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Xiaopeng Huitian commits to Schaeffler flying car powertrains

KAI celebrates first flight of prototype Marine Attack Helicopter

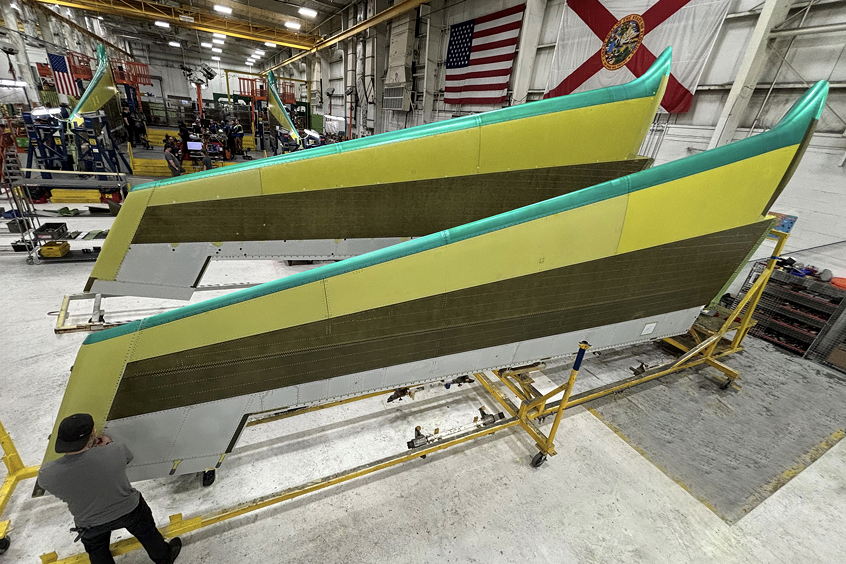

Daher secures long-term lease for Florida aerostructures facility