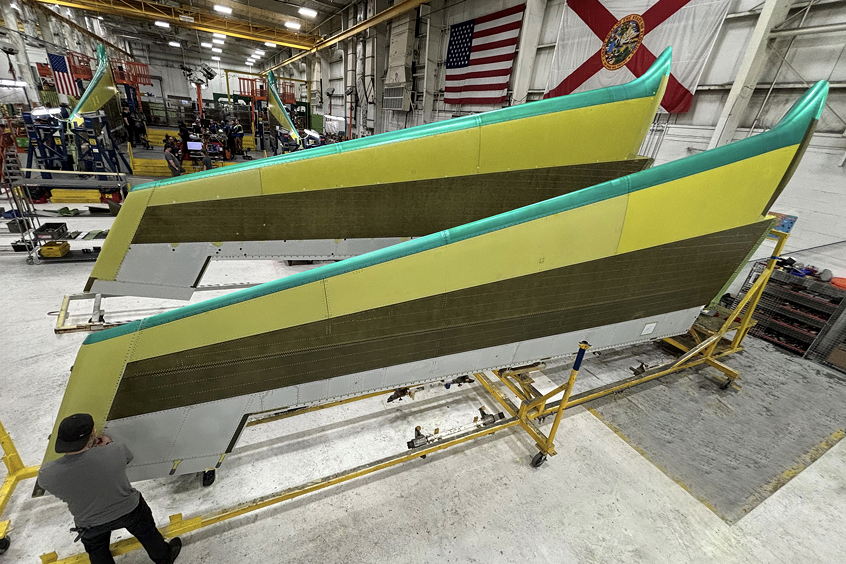

Norsk Titanium US Inc. (Norsk), a global leader in additive manufacturing of aerospace-grade titanium components, announced production deliveries of new Boeing 787 Dreamliner components to Leonardo's Grottaglie Plant, based in South Italy and part of Leonardo's Aerostructures Division. This delivery adds a third production customer to Norsk's growing commercial aerostructures customer base and represents Norsk's first recurring production order from a European Union based Aerospace company.

Using Norsk's revolutionary Rapid Plasma Deposition (RPD) process, Norsk engineers designed Ti-6Al-4V preforms that reduced raw material needs by over 40 percent. Leveraging the RPD industrial process enabled Norsk to create a near-net-shape design, while maintaining the stringent process control and material properties needed for structural applications in Boeing aircraft.

"We are pleased to be Leonardo's supplier," said Karl Fossum, director of customer programs for Norsk. "This delivery marks a significant increase in the number of additively manufactured parts previously manufactured from titanium plate. It also is an important step towards our mission to provide an alternative to titanium forgings in aerospace applications."

| Contact details from our directory: | |

| Norsk Titanium AS | Metal & Alloy Fabrications, Titanium, Additive Manufacturing |

| Leonardo Aeronautics (Alenia) | Airframer |

| Related aircraft programs: |

| Boeing 787 Dreamliner |

| Related directory sectors: |

| Metals |

| Metal Processes |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Xiaopeng Huitian commits to Schaeffler flying car powertrains

KAI celebrates first flight of prototype Marine Attack Helicopter

Daher secures long-term lease for Florida aerostructures facility